Quality Control Process

1. Pre-production inspection:

A: Inspection of raw materials, and make storage records

B: Confirm the color with customer

C: Pre-production sample confirmation and seal

2. Production inspection:

A: Inspection of raw materials, and make storage records

B: Confirm the color with customer

C: Pre-production sample confirmation and seal

3. Sampling inspection at the time of storage, and record

4. Shipment inspection: unpacking confirmation according to the shipment order, and making a record

PRODUCTION INSPECTION CONTENT

1. Use function detection

Test the use function of the product.

2. Safety performance test

A. sewing products, we will have a needle check (check if there is a needle broken inside when sewing). Make sure that consumers are not harmed and consumers are more comfortable and safe to use.

B. Food-grade products, check whether it can pass relevant certification and customer requirements.

3. Quality inspection:

A We will test the quality of each mop pole.

B Water spray products, we will test whether the water is normal before packaging.

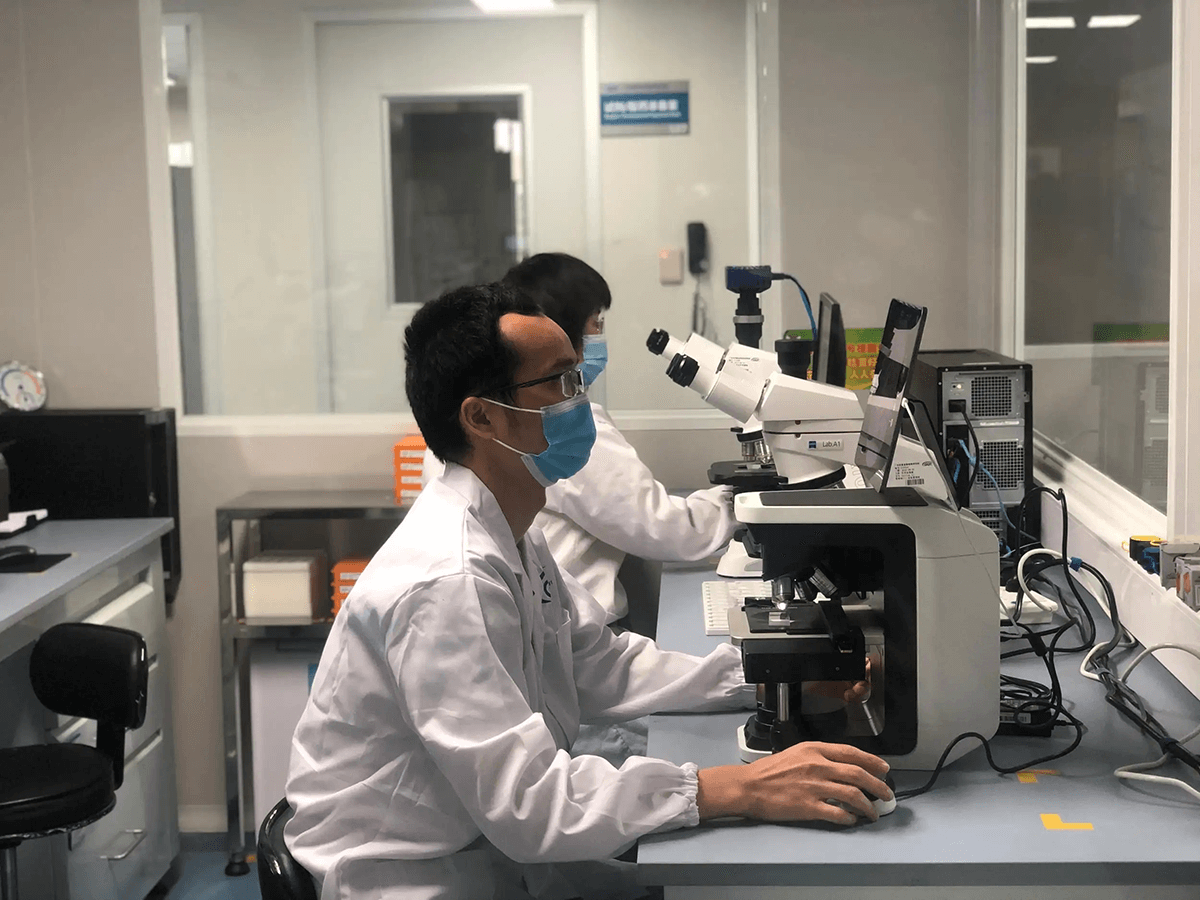

C two fabric inspection machines inspect the incoming materials, rejecting defective products and non-conforming products from the beginning.